Case Study: Terminating and Testing OM3 Fibre Optic Cable at a Water Treatment Work in West Sussex

Our company was recently contracted by a water treatment works in West Sussex to terminate and test an OM3 fibre optic cable. The work was required to upgrade the facility's network infrastructure and improve its overall performance.

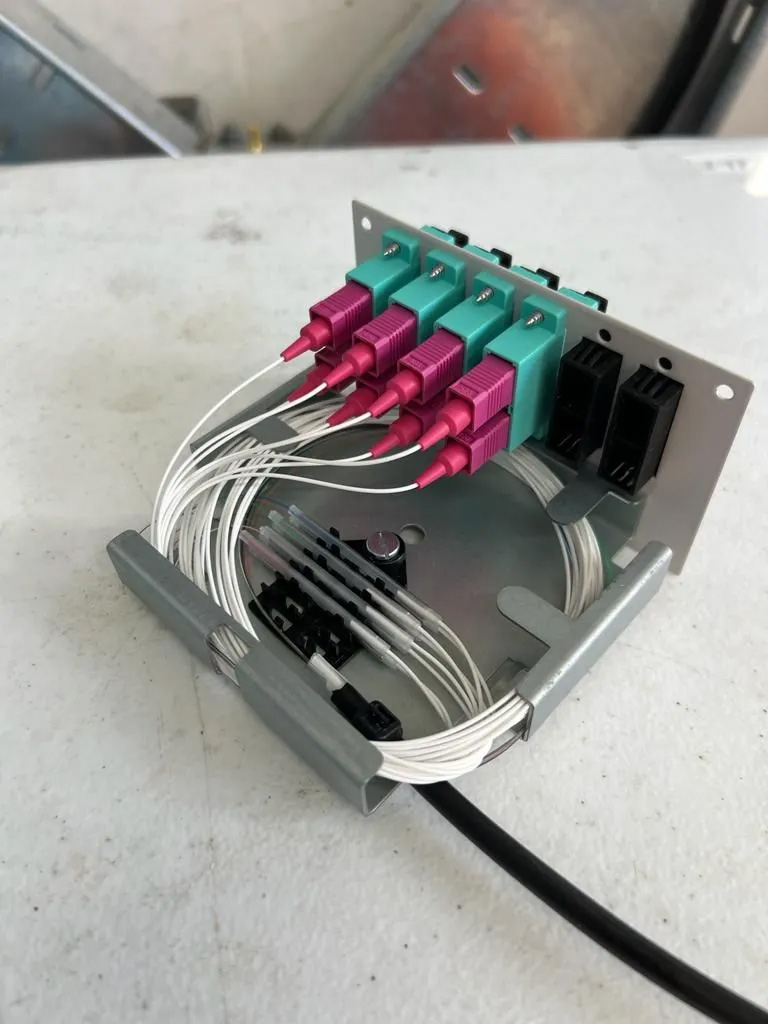

The first step was to terminate the fibre optic cable. This was done using a fusion splicer, which is a machine that uses heat to join two pieces of optical fibre together. The splicer was carefully calibrated to ensure that the connection was made perfectly.

Once the fibre optic cable was terminated, it was tested using a light source and a power meter. The light source was used to send a signal down the cable, and the power meter was used to measure the strength of the signal at the other end. The results of the test showed that the cable was able to transmit data at high speeds without any loss of signal.

Benefits of Terminating and Testing OM3 Fibre Optic Cable

There are many benefits to having OM3 fibre optic cable terminated and tested. Some of these benefits include:

- Improved network performance: OM3 fibre optic cable can support speeds of up to 10 Gbps, which is much faster than traditional copper cable. This can lead to improved performance for applications such as video streaming, VoIP, and file sharing.

- Increased security: OM3 fibre optic cable is more difficult to tap into than copper cable, which can help to protect sensitive data.

- Reduced downtime: OM3 fibre optic cable is less likely to be damaged than copper cable, which can help to reduce downtime caused by network outages.